GMT: Your Trusted Partner for Ultra Precision CNC Turned Parts Manufacturing

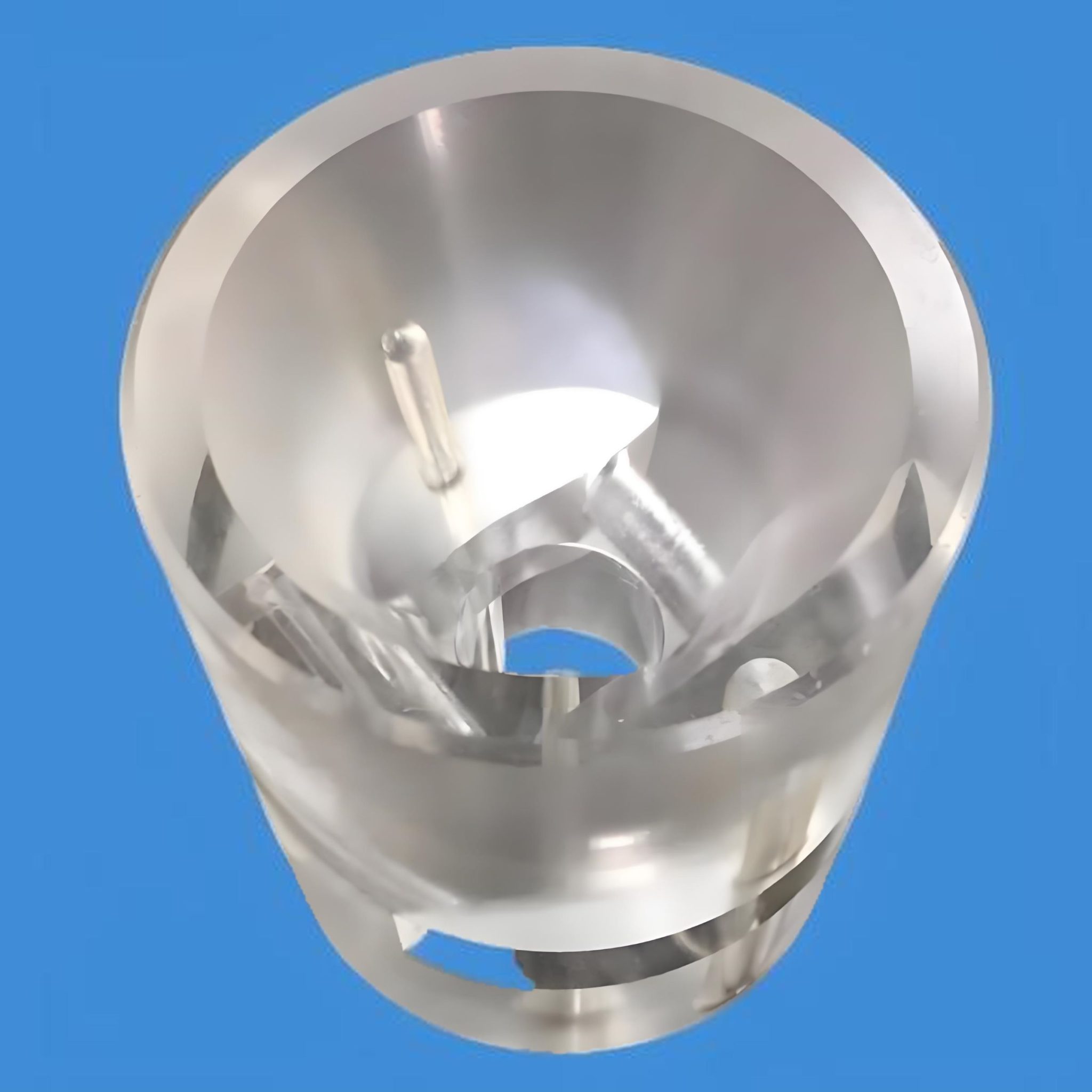

As a leader in advanced machining solutions, GMT specializes in producing ultra precision CNC turned parts for industries demanding micron-level accuracy and unwavering reliability. Leveraging state-of-the-art CNC turning technology, we deliver components that exceed ISO quality standards, ensuring flawless performance in mission-critical applications.

Why Choose GMT’s CNC Turning Expertise?

Our computer-controlled lathes execute rotational machining with 0.005mm repeatability, creating cylindrical components that meet exacting specifications. This technological edge enables us to handle:

- 50+ engineering-grade materials (stainless steel, titanium, PEEK, etc.)

- Complex geometries with tight tolerances (±0.001mm)

- Batch sizes from prototype (1-100pcs) to mass production (10,000+ units)

Industry-Specific Solutions with Ultra Precision

From ultra precision CNC turned parts for minimally invasive surgical tools to vibration-resistant components for aerospace systems, our manufacturing capabilities span:

Medical Technology

- Sterile implant components

- MRI-compatible sensor housings

- Laparoscopic instrument joints

Automotive Innovation

- Fuel injection nozzles

- Transmission system bushings

- EV battery thermal management parts

Electronics Manufacturing

- 5G antenna connectors

- Micro-optics lens barrels

- Semiconductor wafer handling components

Certified Excellence Through Continuous Innovation

GMT maintains competitive advantage through:

- Annual 15% R&D budget increase

- AS9100D & ISO 13485 certified facilities

- Real-time SPC (Statistical Process Control) monitoring

- Cross-trained engineering team with 20+ years average experience

Streamlined Production Workflow

Our vertically integrated service model ensures:

✓ DFM analysis within 24 hours

✓ 98% on-time delivery rate

✓ Full traceability with material certs

✓ ROI-optimized machining strategies